Tuesday, December 5, 2017

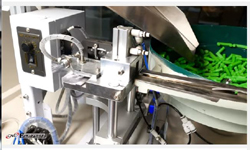

“The Lockdowel, glue-less, snap-together assembly method for cabinets and furniture is a game changer in this industry,” Chris Corrales Owner of CNC Factory says. “This is just the kind of technology breakthrough CNC Factory can incorporate quickly and expertly, and indeed we have, with the Scorpion Lockdowel LDR machine,” Corrales says. The LDR machine is equipped with third generation robotics technology, precise laser measuring and is designed for one operator, even for large panels.

CNC Factory designs, builds and manufactures CNC (Computer Numerically Controlled) machines in their Santa Ana facility. “With CNC Factory located in the United States, we integrate new technology into CNC systems quicker and more skillfully than any other CNC manufacturer in the world,” Corrales added further.

Andy Patel, Owner of Designer Closets in Orlando, Florida recently purchased a Scorpion Lockdowel LDR Machine, a CNC router, an edgebander and a 3-D Lamination Thermalfoil Press all from CNC Factory to produce the Lazy Lee Spinning closets. Lazy Lee incorporates Lockdowel fasteners for very quick assembly and hidden fasteners, without using screws, glue or cams.

“Lockdowel will allow our products to be assembled very quickly, and then disassembled and reassembled should the customer need to move to another home. Thus the tagline – Closets for Life!” Patel explains. Patel is pleased with the quality the CNC Factory machines deliver for the Lazy Lee Spinning Closets and other lines of storage solutions, but says he really chose the company as his supplier of equipment for the owners.

“We chose CNC Factory by qualifying the people behind the design, manufacturing and servicing of the equipment, as the after sales service and attitude of the people supporting the purchase is a lot more important than the original purchase,” Patel says.

“I know I’m working with people I like and get along with,” Patel explains. “Should I have an issue, who I am working with and how issues get resolved is very important. Chris and his team deliver in-house tech support and treat me as a friend they know, and not just a problem they need to process.”

“I know I’m working with people I like and get along with,” Patel explains. “Should I have an issue, who I am working with and how issues get resolved is very important. Chris and his team deliver in-house tech support and treat me as a friend they know, and not just a problem they need to process.”

Patel trusts CNC Factory team for the best service and purchased two of his four machines sight unseen. “That’s saying a lot. I didn’t even need to see the machines in person because I trust the company and the owner that much!” Patel concluded.