Tuesday, April 9, 2024

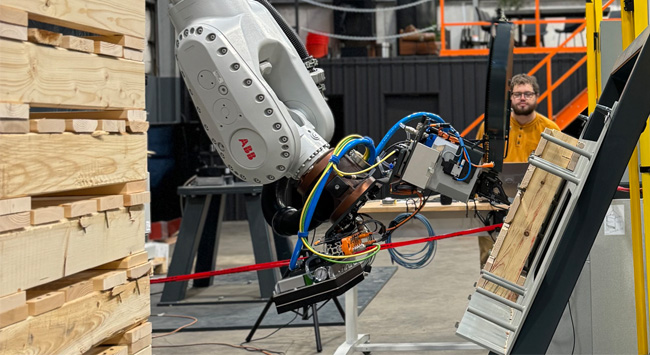

Canopy Lumber Products, a manufacturer of custom pallets and shipping solutions, partnered with 7robotics to enhance worker safety, improve quality management, and increase production capacity in its company. With the goal to make use of an innovative approach, it has implemented a Robotic Pallet Building System with the help of 7robotics.

Product Overview

FLEXIBLE MANUFACTURING

The Robotic Pallet Building System by 7robotics offers versatility and efficiency. It can accommodate three SKU variations: standard 24”x24”, standard 24”x20”, and specialty 24”x24”. There is also the ability to add more SKU variations as Canopy grows their product offerings. The system’s tooling features include drop detection, product present verification, air pressure feedback, safety air valve, empty nail gun detection, and auto nail gun lubrication.

SAFETY FEATURES

The system ensures operator safety through three safety zones, allowing continuous operation of the robotic nailing and stacking while a forklift unloads stacked pallets simultaneously. On the other end, an area scanner activates safety measures during table rotation to prevent the operator from being hit or injured by the turn table. Moreover, a safety air valve releases air pressure when not in use, reducing risks from operator errors or equipment malfunctions.

HMI FEATURES

The Human-Machine Interface (HMI) facilitates seamless operation with features like product selection, safety status indicators, nail depth offset adjustment, job and lifetime counters, stack counters, and estimated nail count.

SUPPORT & MAINTANENCE

Remote access supported by wireless cameras and virtual twin technology enables monitoring and adjustments. Active and historical error logs assist in troubleshooting and maintenance.

CLIENT TESTIMONIAL – Prior to partnering with 7robotics, Canopy Lumber Products was skeptical about the feasibility of robotic pallet assembly. However, the experience exceeded expectations. The 7robotics team demonstrated professionalism, dedication, and expertise throughout the project.

POSITIVE OUTCOMES

After a few months of production, Canopy experienced significant improvements in employee safety and operational efficiency. Notably, the system eliminates the need for manual nail gun handling and automates pallet stacking, enhancing safety and productivity.

PROCESS OPTIMIZATION

The introduction of the robotic cell transformed Canopy’s operations by improving profitability on smaller production runs. With reduced setup times, the company can swiftly switch between products, leading to increased flexibility and profitability.

COST SAVINGS

The implementation of the Robotic Pallet Building System resulted in notable time savings. The streamlined product changeover process and consistent output have increased daily pallet production, translating into tangible efficiency gains.

In collaboration between Canopy Lumber Products and 7robotics exemplifies the transformative impact of automation on safety, efficiency, and profitability in manufacturing operations. By embracing cutting-edge technology and partnering with experienced automation experts like 7robotics, companies can unlock new opportunities for growth and success.

Read more news on 7robotics

Tags: 7robotics, Canopy Lumber Products, Pallet building system, wood and panel, woodworking, woodworking and manufacturing, woodworking USA